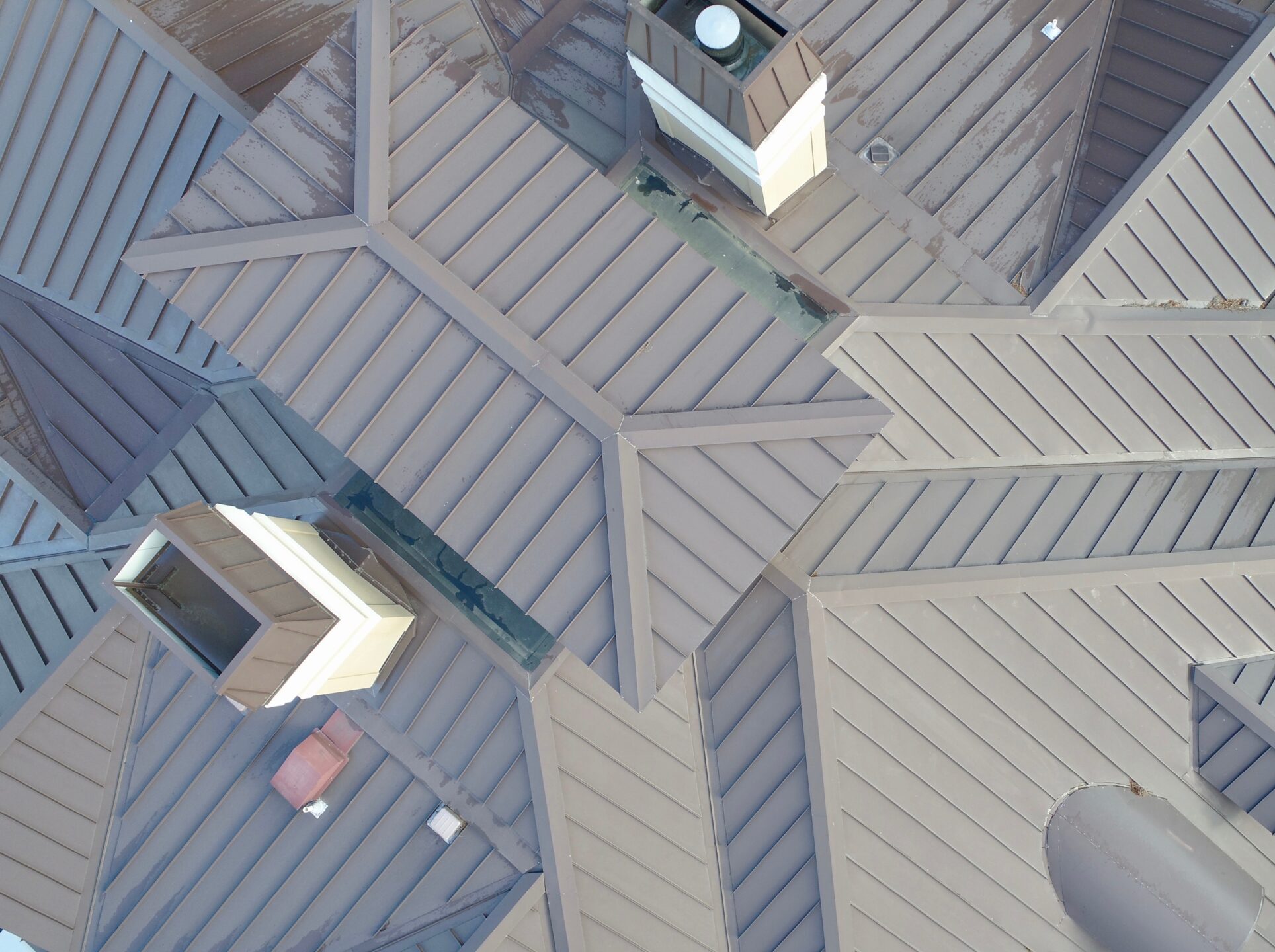

Standing seam metal roofs are one of the most attractive and durable steep slope roofing systems available today. It dresses up a commercial building beautifully, and can be used as an accent feature on buildings with combined high and low slope roofs. Whether you have a shopping center in Sedona or an office complex in Phoenix, standing seam metal is one of the most universal, attractive, and durable roofs you can buy.

ABOUT STANDING SEAM METAL ROOFING

Standing seam metal can be used on slopes as low as 2″ for every foot, depending on the product. It consists of entirely concealed screws and clips holding the metal in place, with standing seams where the panels are connected, hence its name. Typically, the panels come in 12″, 16″, or 18″ wide panels, and in 22, 24, or 26 gauge material, though other options can be ordered. They are factory coated with an enamel, or can be ordered bare to rust in the elements.

At M&M Roofing, our most common metal roof product is Western Lock by Western States Metal Roofing. Headquartered here in Arizona in Phoenix, Western States Metal Roofing covers their products with a 30 year fade warranty and their products are built to withstand the sun and temperatures across the state. These are durable and totally waterproof when installed correctly, for a lifetime product. It’s considered to be a lifetime product once installed, if done properly – here in Arizona, the main concern with standing seam is generally sun fading of the factory applied enamel. Most reputable manufacturers warrant against this for around 30 years – it can be repainted once it has started to fade, but at that point it will become a regular maintenance item.

THE STANDING SEAM METAL ROOFING SYSTEM

Standing seam metal roofs can be installed over solid decks, or open purlins depending on the application. On a solid deck, we would lay down a high temperature self-adhered underlayment in case of any water getting through and to help with condensation, then the standing seam metal system is installed. We can purchase pre-made metal flashings like rake trim, drip edge, ridge, and more through the manufacturer, or we also have the capabilities to fabricate our own metal flashings in house, allowing us to custom make flashings for around chimneys or other typically problematic areas.

To install the panels, concealed clips are installed on one edge of the panel, holding it down to the deck. Then, the next panel is overlapped onto that panel rib, locked in using the standing seam, and fastened down with concealed clips on its leading edge.

LIFESPAN AND WARRANTIES

A standing seam metal roof should last 50 or more years, depending on the sunlight hitting it, climate conditions, and exposure. When we use high quality underlayment, the roofing system will perform for decades before that underlayment starts to decay.

ABOUT M&M ROOFING

M&M Roofing has been installing standing seam metal roof systems across Arizona since 1984. We service the entire state, including Tucson, the Phoenix metro (Queen Creek, Gilbert, Chandler, Phoenix, Tempe, Scottsdale, Glendale, Goodyear, Avondale, Peoria and outlying areas), Prescott, Flagstaff, Kingman, and everywhere in between. Give us a call to schedule a free consultation.